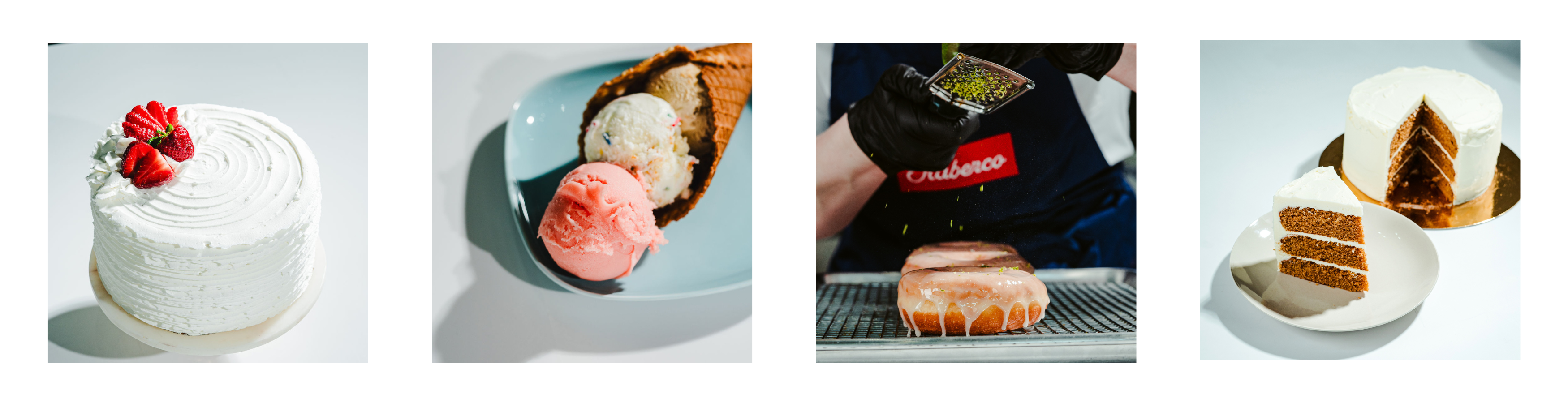

How to Scale Small-Batch Magic Without Losing the Art

Scaling Without Selling Out: Keeping the Soul in Every Batch

1. Start with Your North Star: The Flavor Promise

Before you scale it, define it.

Every great product starts with a feeling. A flavor. A moment. But unless you know exactly what makes it yours, you can’t protect it as you grow.

Is it the tang of a small-batch citrus reduction? The creaminess from a slow-cooked custard base? The visual vibrancy of real fruit purée?

Document your flavor DNA. Lock down a gold standard sample—a reference point that travels with you through every phase of scale.

2. Know the Enemies of Scale

- Texture shifts: Mousses may lose aeration. Sauces may separate.

- Flavor balance changes: Over-extraction in large infusions or underwhelming spice notes in diluted batches.

- Cook times & cooling curves: A few extra minutes or degrees can change the final product.

- Ingredient sourcing issues: Local ingredients may have seasonal limits or regional inconsistencies.

3. Partner Early with the Right People

4. Design with Scale in Mind (But Don’t Compromise)

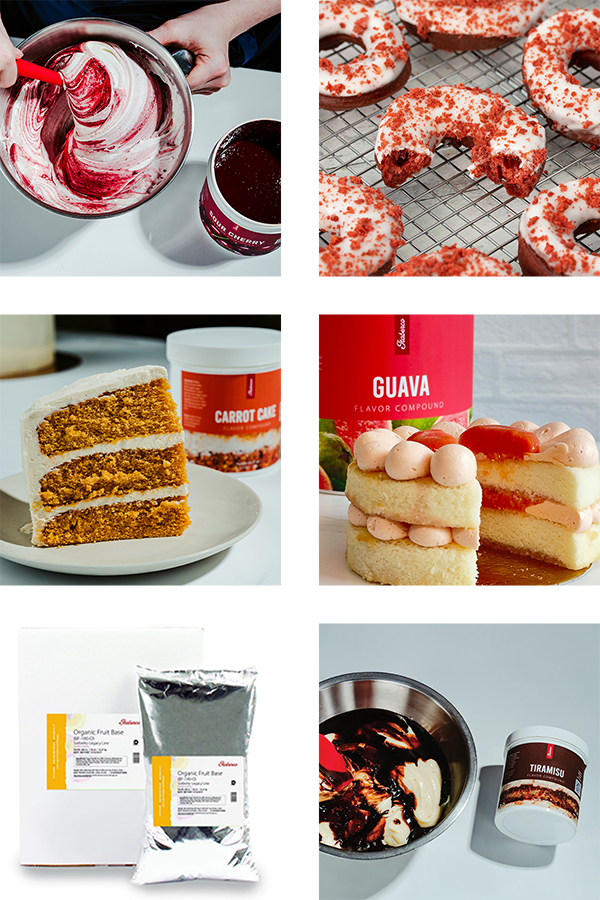

- Choose shelf-stable flavor compounds that retain richness without requiring refrigeration or reconstitution.

- Standardize steps that don’t impact quality—and protect the ones that do (e.g., hand garnishing, slow infusions).

- Understand the shelf life and storage requirements of your product at a commercial level.

5. Flavor Integrity = Brand Integrity

- Run side-by-side taste panels at every phase of your scale-up.

- Train yourself (and your team) to spot subtle changes.

- Resist the urge to take orders you can’t fulfill with consistency.

6. Celebrate Your Evolution

- Still using Madagascar vanilla? Say so—proudly.

- Did you double your kitchen size but still use the same copper pot? Post a side-by-side photo.

- Keep your voice, your values, your visual identity—even as your product reaches more people

Growth Without Losing Your Magic

Scaling is not a betrayal of your craft—not if you do it with intention. With the right partners, the right process, and the right priorities, you can go from hand-crafted to high-volume without selling out.

At Itaberco, we help brands scale without compromise—preserving the soul of your product in every batch.

Let’s grow—and keep the magic intact.

Explore Our Flavor Solutions →